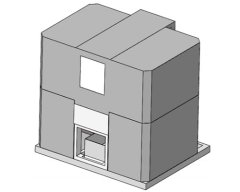

CHTXQ-倒挂380宝石切割机技术参数 Main Specifications

设备用途:本机型的刀架为三罗拉刀架,罗拉长度为380mm,机型主要为满足半导体生产加工的企业,具有提高待切割件的切割精度和提高表面粗糙度的效果。

Equipment use: The tool holder of this model is a three-roller tool holder, the length of the roller is 380mm, the model is mainly

to meet the semiconductor production and processing enterprises, with the effect of improving the cutting accuracy of the parts

to be cut and improving the surface roughness.

CHTXQ-倒挂380宝石切割机技术特点 Brief Introduction

1、此机器为上置料板摇摆工作台,材料由上向下进行切割。

2、摇摆驱动器驱动曲柄旋转,滑动销轴通过长滑孔驱动上置料板与切割料的组合左右摆动至特定的⻆度位置,先进行点接触或短线接触进行切割。

3、切割金刚石线反复交替在两条切割面上做切割运动,使切割面对切割金刚石线的阻力变小、切割效率提高减小了金刚石线断线的概率。

4、装载面积为:380mm*200mm*160mm。

5、罗拉采用双锥定位,装卸方便,高速运转平稳,精度可靠。

6、主轴精度≤0.01mm,采用结构防尘,运行更稳定,拆装更方便。

7、操作使用方便,自动升降护罩,工作台全面展开,便于材料装卸和罗拉拆装。

1. This machine is a rocking table for the upper material plate, and the material is cut from top to bottom.

2. The swing driver drives the crank to rotate, and the sliding pin drives the combination of the upper material plate and the cutting material to swing left and right to a specific Angle position through the long slide hole, and the point contact or short line contact is made to cut first.

3, the diamond cutting line repeatedly alternates the cutting motion on the two cutting surfaces, so that the cutting resistance to the cutting diamond line is smaller, the cutting efficiency is improved, and the probability of the diamond line breaking is reduced.

4. Loading area: 380mm*200mm*160mm.

5, the roller adopts double cone positioning, easy loading and unloading, stable high-speed operation, reliable accuracy.

6, spindle precision ≤0.01mm, the use of structural dust (patent No. ZL201320681902.7), more stable operation, more convenient disassembly.

7, the operation is easy to use, automatic lifting shield, the workbench is

高级会员

高级会员 已认证

已认证