|

参考报价:电议 型号:

产地:香港 在线咨询

|

ROLLING ELEMENT BEARING FATIUGE LIFE TESTER CM - 9053

PURPOSE

The life of an individual rolling bearing is defined as the number of revolutions bearing endures before the first sign of fatigue (flaking, spalling) occurs on one of its rings or rolling elements. Purpose of this rig is to determine life of a loaded bearing. Dynamic load rating of a bearing is based on the fatigue life L10. This is the life which 90% of the bearings in a sufficiently large group can be expected to attain or exceed. When large number of identical bearings have been tested, L10 and hence, dynamic load rating can be estimated.

Any bearing which is amicable with the mounting and loading arrangement of the rig can be tested. This includes deep groove, angular contact, taper roller and cylindrical roller bearings.

DESCRIPTION

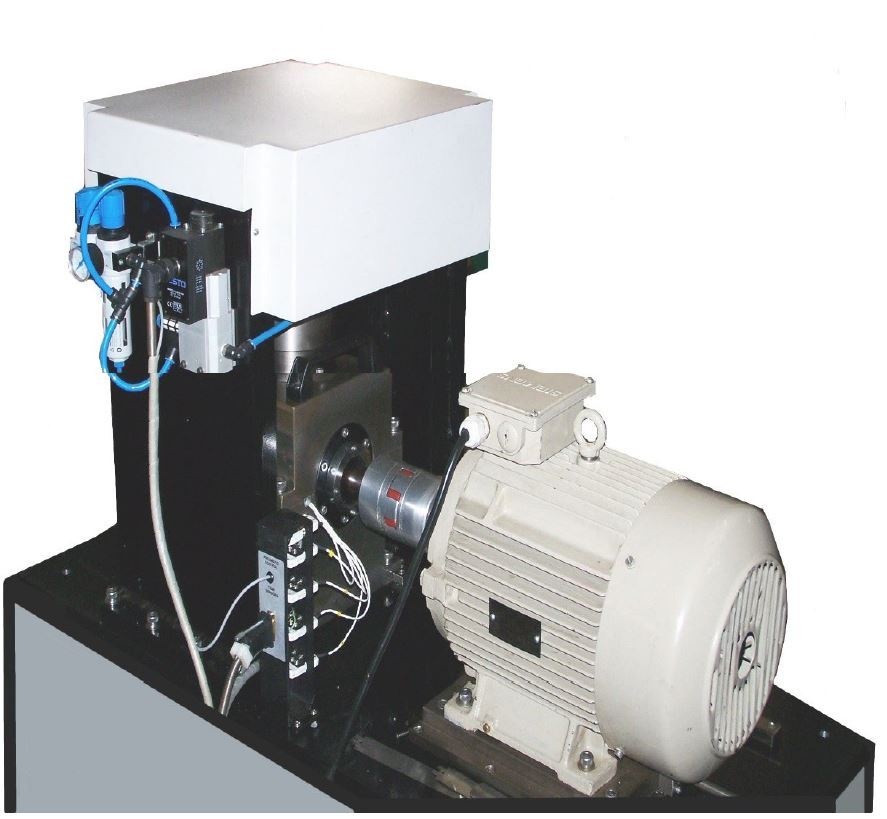

Schematic diagram of the test rig is shown in figure. Four identical bearings are mounted on a shaft. Axial and radial loads are applied when bearings are running. Failure of a bearing is sensed by abnormal increase of either vibration or temperature. At this point, the rig stops. Number of revolutions to fail are recorded.

The test rig consists of following sub-systems:

1. MECHANICAL ASSEMBLY

Each bearing size will require a matching shaft, set of spacers and adaptor rings (not shown in figure), so that they can be mounted in the housing for conducting tests. The housing is split for convenient assembly. Temperature sensors are mounted on the adaptor rings so that they touch the outer race. Vibration sensor is mounted on the housing. The ratio of the maximum to minimum bearing diameter, which can be accommodated in a test station, is 2. This is due to the load-speed requirement and dimensional constraints. Hence, the test requirements are covered in multiple test stations. Num-ber of test stations required depends on the span of test parameters. Each test station is a stand alone, independent unit.

2. LUBRICATION SYSTEM

Test bearings can be lubricated in any of the following ways:

1. Pre-packed with grease for life

2. Partial submersion in oil sump

3. Oil jet with recirculation system consisting of lubricant tank, pump, filters and delivery nozzles

3. LOADING SYSTEM

Test loads are axial and radial. Axial load is applied to the outer ring of outermost bearing on non-driven end of the shaft. This load is transmitted to the inner ring through the rolling elements. It is then transferred to the next bearing by a spac-er, and in this manner all the bearings are loaded in series. Once axial load has been applied, radial loading starts. This procedure minimizes non-uniformity in axial loading which may arise because of frictional force due to radial load.

4. DRIVE

One end of shaft is coupled to an induction motor. Test speed is set by a variable frequency inverter. Motor and coupling are balanced to minimize ambient vibration level of the system.

5. INSTRUMENTATION

The following sensors monitor various parameters:

? Load sensor for the measurement of axial load

? Load sensor for the measurement of radial load

? RPM sensor for test speed

? Four temperature sensors for bearing temperature at the outer ring

? Vibration sensor mounted on the housing

? Elapsed time meter

? Lube oil filter clog switch

6. MACHINE CONTROL SOFTWARE

Test rig is controlled through a PC. Machine control software facilitates preprogramming of test schedule. Test speed and radial load schedule are entered before the start of test. Speed and load can be either held constant or vary in steps or ramped when any of the bearing temperature exceeds user defined limit. Similarly, when RMS level of vibration ex-ceeds, set limit and stays continuously higher for more than one minute, a bearing is deemed to have failed, and test ter-minates. Whenever test stops, a message indicating its cause is displayed.

7. DATA ACQUISITION

Data acquisition is based on Labview 7.1. It records the following parameters:

? Axial and radial test loads

? Four channels of bearing temperature

? RMS Vibration level

Acquired data is displayed graphically online. It also monitors status of safety interlocks related to lubricating oil and loading system. When any parameters go beyond preset limit, commensurate action will be taken to ensure safety of the rig, sample and operator.

Post processing module allows viewing of the acquired data in several ways. Test results of a test can be viewed as graph. Results of several tests can be viewed together for comparison. Span of viewing can be selected and zoomed. Test results can be printed. They can also be exported to other software. The software is customized to include user’s logo, identification, address and similar information.

8. SAFETY INTERLOCKS

? Over voltage

? Under voltage

? Single phasing

? Motor over current

? Test load beyond preset limit.

? Lube oil filter clog.

? Bearing temperature exceeding preset limit.

? Vibration level exceeding preset limit.

? Safety guards

? ELCB

SPECIFICATIONS

It may not be possible to meet target specifications in one test station. Following table depicts a set of three test stations to cover 10 to 100 mm shaft diameter range. Test stations to meet your requirements may differ in number and specifica-tions.