海旭磨料 |

参考报价:20000 型号:JIS#12-#12000

产地:中国河南郑州荥阳高村工业园 在线咨询

|

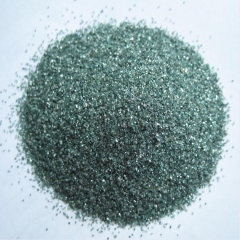

silicon carbide green绿碳化硅black黑碳化硅

产品卖点:

1、郑州市海旭磨料有限公司建于1999年

2、提供三高磨料——高清洁、高堆密、高纯度

a.高清洁度

磨料放入玻璃杯中加水搅拌,水溶液清澈透明,少量悬浮物。

b.高堆积密度,颗粒圆度值低

磨削效率高,工件表面光洁度好。

c.高纯度:Al2O3含量99.2%以上

3、付款后24小时内闪电发

碳化硅介绍:

SIC introduction

性能特点:碳化硅是用石英砂、石油焦(或煤焦)、木屑(生产绿色碳化硅时需要加食盐)等原料在电阻炉内经高温冶炼而成,在电阻炉内经高温冶炼而成,呈黑色或者绿色不透明体,六角形结晶,莫氏硬度为9.16-9.5。仅次于金刚石和碳化硼,性能脆而锋利并且有一定的导电性

Peformance:SIC is made from quartz sand and petroleum coke(smokeless acetylene) (salt added in the produce of green silicon carbide) as the mainraw material.it is made via light resistance from hydrometallurgical,it is black opaque body hexagonal crystal and MOHS -hardness in the 915-9.5,which is after diamond and boron carbide with crisp and sharp performance and certain degree of conductive heat

碳化硅有黑碳化硅和绿碳化硅,①黑碳化硅含SiC约98%,其韧性高于绿碳化硅,大多用于加工抗张强度低的材料,如玻璃、陶瓷、石材、耐火材料、铸铁和有色金属等。②绿碳化硅含SiC约99%,自锐性好,绿碳化硅适宜磨削硬质合金和硬脆金属及非金属材料,如铜、黄铜、铝和镁等有色金属和宝石,光学玻璃,陶瓷等非金属材料。绿碳化硅也可用于耐火材料和应用在电子半导体行业

Silicon carbide have two color ,black silicon carbide is higher toughness than green silicon carbide with sic purity 98%,it have been used for processing glass,ceramic,stone, refractory materials ,cast iron and other metal. Green silicon 's purity can reach to 99%, With higher purity of crystallization and hardness, abrasive tools made of it are suitable for processing hard and brittle materials such as: hard alloy, titanium alloy, bearing steel,non-ferrous metals like copper, brass, as well as some non-metallic materials including: glass, agate, electrical ceramic, quartz products, rock, gem, ceramics and so on

产品用途:

Usage:

1.碳化硅使用加工低抗张强度的金属及非金属,还广泛用于耐火材料和电子工业

Sic processed by low-intensity metal and non metallic and also can be used in fire-resisting materials and the electronic industry

2.有色金属冶炼,钢铁行业, 冶金选矿行业,建材陶瓷,砂轮工业方面,节能方面

Colored metal 2.iron and steel industy constructing materials and ceramic 5.Energy-saving

3.制造耐火材料,高温陶瓷,电阻发热体,磨料磨具,重结晶碳化硅制品的重要原材料

Usage:It is the important raw materials of high refractories manufacturing ,high-temperature ceramics,body heat resistance, abrasives and recrystallized silicon carbide.it is crushed on the

1,用于耐火材料,炼钢增碳剂 Used for refractory,carbon agent

属性 Properties 规格Type

| 0-1, 1-3, 0-10, 1-10mm | 100-0 200-0 320-0 | |||

保证值 Guarantee Value | 典型值 Typical Value | 保证值 Guarantee Value | 典型值 Typical Value | ||

化学成分 Chemical Composition | SIC | ≥97 | 97.5 | ≥97 | 97.5 |

F.C | ≤0.4 | 0.3 | ≤0.4 | 0.25 | |

Fe2O3 | ≤0.3 | 0.25 | ≤0.3 | 0.20 | |

H2O3 | ≤1 | 0.30 | ≤1 | 0.35 | |

冶金用碳化硅可以按照客户特殊需求加工生产不同含量和不同粒度的产品

2,用于磨料,喷砂,研磨,抛光Used for abrasives,blasting,grinding

属性 properties

规格Type | 粒度砂Grains | ||

8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

保证值 Guarantee Value | 典型值Typical Value | ||

化学成分 Chemical Composition | SIC | ≥98 | 98.5 |

F.C | ≤0.2 | 0.1 | |

Fe2O3 | ≤0.2 | 0.15 | |

H2O3 | ≤1 | 0.3 | |

3,用于磨料,研磨,抛光等 Used for abrasives ,lapping,Polishing

属性 properties 规格 Type | 微粉 Micropowder | |||

“W”标 | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

“FEPA”标 | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | |||

“JIS”标 | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# | |||

保证值Guarantee Value | 典型值Typical Value | |||

化学成分 Chemical Composition | SIC | ≥97 | 97.5 | |

F.C | ≤0.3 | 0.2 | ||

Fe2O3 | ≤0.2 | 0.15 | ||

H2O3 | ≤1 | 0.3 | ||