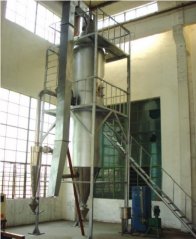

应用概述 General of applications

★喷雾干燥是液体工艺成形和干燥工业中*广泛应用的工艺。*适用于从溶液、乳浊液、悬浮液和可泵性糊状液体原料中生成粉状、颗粒状产品。因此,当成品的颗粒大小分布、残留水分含量、堆积密度和颗粒形状必须符合精确的标准时,喷雾干燥是一道十分理想的工艺。

★Spray drying is a wide applied process in liquid process shaping and drying industry. Particularly it is suitable for producing powder, granule or block solid product from solution, emulsion, suspending liquid and pumped paste liquid. Therefore when the distribution of granule size, final moisture, bulk density, granule shape of finished product must be conformed to accuracy standard, the spray drying is an ideal process.

设备特点 Features of equipment

★干燥速度快,料液经雾化后表面积大大增加,在热风气流中,瞬时就可蒸发95%-98%的水分,完成干燥时间仅需5-40秒钟,特别适用于热敏性物料的干燥。

★产品具有良好的分散性、流动性或溶解性,由于干燥过程是在空气中完成的,所以基本能保持于液滴相近似的球状,良好的分散性、流动性和溶解性,使产品纯度高质量好。

★生产过程简化,操作控制方便。通常用于湿含量40-60%的溶液(特殊物料可达90%)能一次干燥成粉粒产品,干燥后不需粉碎和筛选,减少生产工序,提高产品纯度。对产品粒径,松密度、水份,在一定范围内可通过改变操作条件进行调整,简化了生产工艺流程,控制和管理都很方便。

★Quick drying speed, the surface area of material liquid through atomizing is increased greatly. In hot air stream, 95% to 98% of moisture can be evaporated at the moment. Particularly suitable to finish drying thermal sensitive material.

★The product made by the machine has good uniformity, fluidity, solubility, high pure, and high quality.

★The productive process is simple and the operation control is very convenient. For liquid containing 40-60% of damp(for special material, may be 90%), it can be dried to powder product through drying one time. After dried, it is not necessary to crush and sieve. So it reduces productive procedure and raises the purity of product. For the size, bulk density and moisture of product can be adjusted within certain scope through changing operation condition. The control and management are very convenient.

| 规格Specification 项目Item | 5 | 25 | 50 | 100 | 150 | 200-300 |

入口温度 Tep of inlet air | ≤350℃ |

出口温度 Tep of outlet air | ≤80℃~90℃ |

蒸发量(kg/h) Evaporated capacity | 5 | 25 | 50 | 100 | 150 | 200-300 |

传动形式 Transmitted | 压缩空气驱动 Compressed air | 机械传动 (Machine transmission) |

转速(rpm) Rotating speed | 25000 | 22000 | 21500 | 18000 | 18000 | 15000 |

喷雾盘直径(mm) Dia.of atomizing disk | 50 | 120 | 120 | 120 | 150 | 180-340 |

热源 Heat source | 电 Electricity | 电 Electricity | 电+蒸汽、燃油、煤汽 Electricity+steam,oil fuel,gas | 电+蒸汽 Electricity+steam | 电+蒸汽、燃油、煤汽 Electricity+steam,oil fuel,gas | 由用户自行解决 By customer |

电加热功率(kw) Power of electric heater | 9 | 45 | 60 | 81 | 99 |

|

干粉回收率(%) Yield of dry power | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |

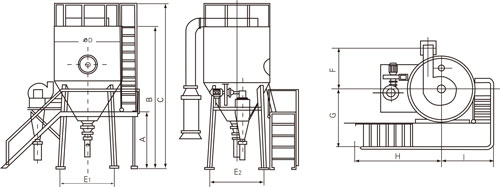

主机尺寸 Installation size for reference | A(mm) | 1000 | 1290 | 1730 | 2500 | 2800 | 根据实际情况确定 Decided in accordance with actual condition |

| B(mm) | 2100 | 3410 | 4245 | 5300 | 6000 |

| C(mm) | 2300 | 4260 | 4645 | 6000 | 6700 |

| ØD(mm) | 1060 | 1800 | 2133 | 2560 | 2860 |

| E1(mm) | 1050 | 1200 | 1640 | 2100 | 2180 |

| E2(mm) | 1050 | 1200 | 1640 | 2100 | 2180 |

| F(mm) | 750 | 1000 | 1250 | 1750 | 1970 |

| G(mm) | 530 | 1700 | 1750 | 1930 | 2080 |

| H(mm) | 530 | 1300 | 1800 | 2600 | 3050 |

| l(mm) | 530 | 1550 | 1600 | 1780 | 1960 |

所有参数仅作参考,视物料情况,本公司拥有变更权利,并不另行通知。

All datas are used for reference only. According to the condition of material, our factory has the right to change but not notice, pardon!

安装参考图 Reference drawing of installation

金牌会员

金牌会员 已认证

已认证