FT-3500粉体压缩强度测试仪

FT-3500 Powder compression strength tester

1. 原理和理论Principle and theory:

颗粒在压缩时要经历初步压缩、颗粒重排、初始结构形成、弹性形变、塑性形变、颗粒破碎、结合键形成、进一步压实及卸去压力后的弹性恢复等系列变化,颗粒结构被破坏并发生重组形成新的结合键及压缩体;通过对粉体施加屈服强度变形所需的主应力,来分析粉体的体积、空隙率,压缩度与屈服强度关系即(主应力与粉体密度的变化关系),采用经验方程法:Heckel、Kawakita、Adams方程及川北方程线性回归方程的压缩理论来分析粉体颗粒新品、研发固体产品比如在药物配比及工艺选择方面及压实密度对压力的要求等的预测性分析工具.

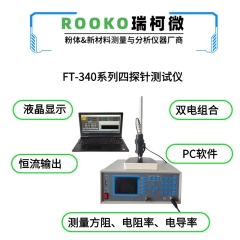

本机型还可以实现粉体电阻、电阻率、电导率的测量(导体粉末),可通过粉体压缩与阻抗的变化关系或者粉末体压缩过程中的静电测量(绝缘粉体颗粒).通过电性能的变化来判断粉体压缩特性.

During compression , particle need undergo preliminary compression, particle rearrangement, the initial structure formation, elastic deformation, plastic deformation and grain crushing, combined with the key form, further compaction and of elasticity after removal the stress and so on series of change, such as granular structure destruction and restructuring to form a new bonding and compressed; By applying the principal stress to the deformation of the powder to analyze The volume change of the powder body and the pressure relation,(namely The relationship between primary stress and powder density), the relation between time and yield strength, yield strength and compression height change relations, using the empirical equation method: Heckel, Kawakita, Adams equations and the compression theory of Kawakita’s Equation of linear regression equation to analyze the new powder particles, research and development of solid products such as predictive analysis tools in drug prescription and process selection and Compaction density is required for pressure etc.

This model can realize measurement of powder resistance, resistivity, conductivity( conductor powder),Judging powder’s compression feature through the change of relationship between compression and impedance or powder body ‘s electrostatic measurement In the process of powder compression. (insulation powder particles).

二、压缩成形机理At present, recognized mechanism of compression forming is:

认为粒子受压时,粒子间距离很近,从而在粒子间产生范德华力,静电力等的引力;粒子受压时,其塑性形变使粒子间的接触面积大;粒子受压破碎时,产生的新表面有较大表面自由能;粒子受压变形时,粒子相互嵌合而产生的机械结合力;粒子受压时,由于摩擦力而产生的热,颗粒间支撑点处局部温度较高,使熔点较低的物料部分地熔融,解除压力后重新固化而在粒子间形成 “固体桥”; 在水溶性粒子的接触点处析出结晶而形成的 “固体桥”.

The distance between the particles are very close when pressure apply on the particles, Thus create the van der Waals force, the electrostatic force and so on;When a particle is pressed, its plastic deformation increases the area of contact between particles.When the particle is crushed, the resulting surface has a greater surface free energy When the particles are compressed, the mechanical force of the particles is combined.Particles compression, heat generated by friction, especially the local temperature of the interparticle support point between particles is higher, make the lower melting point material parts melt, After relieve pressure ,curing in between particles to form the “solid bridge “; At the contact point water-soluble particle precipitation crystallization and form of “solid bridge”

三、功能介绍Function introduction:

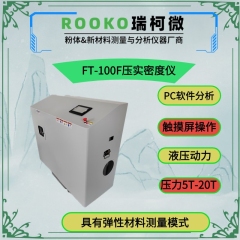

采用液压加压测量系统,7寸触摸屏控制,荷重单元控制系统能采集应力变化数据,可以设置压力、时间数据,位移数据由位移传感器直读,温湿度数据通过传感器获得,多位数的AD芯片来保障数据的分析,自动模式,手动操作模式并存;配置PC软件可以获得应力与粉体密度关系;方程线性变化关系过程数据的分析和曲线图谱,为生产企业和科研院所研发建立数据模型.

Adopts hydraulic constant pressure pressing measurement system, 7 inch touch screen control, high precision load cell stress change control system can precisely collect data, the data can be arbitrarily set pressure, time, displacement direct reading data by displacement sensor, the temperature and humidity data obtained from the sensor, Multidigit AD chip to ensure multibit data analysis, automatic mode, manual mode and multistage set operating modes coexist;Configuring PC software to obtain the stress and powder density curve;The relationship between the time and the yield strength of the powder; Kawakita’s equation of linear regression equation of constant u, v relation and time flow function relation analysis of process data and curve graph, Establish data models for new products and processes developed by manufacturing enterprises and research institutes.

四、适用范围Scope of Application:

食品、药品、粉末冶金、陶瓷、制药、化工、建筑等行业需要经过压缩或者压铸的粉末和颗粒物料;对粉末固体成形性及压缩性在产品开发,中试放大及生产过程中进行分析研究,常用于粉体企业上下游产业,粉体科研院所和大中专院校,为粉体在强度性能,可压缩性数据.

Food, medicine, powder metallurgy, ceramics, pharmaceutical, chemical industry, construction and other industries which need to be compressed or die-cast powder and granular materials. Analysis and research on powder solid forming and compressibility in the development of new products, in pilot plant scale and production, often used in powder enterprise upstream and downstream industries, powder research institutes and colleges, provide reliable data on the strength, compressibility and liquidity of the powder.

测试项目test project | 技术参数technical parameter | 分辨率accuracy |

2. 主应力 principal stress | 5吨;10吨;15吨;20吨;(选购) 1 tons; 5 tons; 10 tons; 15 tons; 20 tons(choose to buy) | 传感器:1级 Sensor: class 1 |

2.位移/ displacement | 位移传感器Pulse displacement sensor | 0.001mm |

3. 位移行程 displacement stroke | 0-20mm | 0.1mm |

4. 控制系统 Control system | 液压控制系统 Hydraulic constant pressure control system |

|

5.显示方式display | 7寸触摸屏+PC软件曲线分析 7 Inch Touch Screen +PC software curve analysis |

|

6. 模具 mould | 内径:20mm;高:25mm ;可选购内径15mm Inner diameter 20mm,height:25mm | 0.1mm |

7.密度density | 0-99.999999g/ml |

|

8.脱模方式Demoulding method | 自动 automatic |

|

9.保护装置/Safety device | 自动诊断、过载保护和急停控制 Automatic diagnosis, overload protection and emergency stop control |

|

10.温湿度范围/ Temperature humidity range | 常温-50度;湿度:20%-98% Room temperature -50℃, humidity:20%-98% |

|

11.时间设置 time setting | 0-99.9S | 0.1S |

12.设备管理功能 Device management function | 密码设置及数据管理 Password setting and data management. |

|

13.使用环境要求 Environmental requirements | 仪器使用环境要求:requirements for instruments: 工作温度:-10℃-40℃,湿度:≤65%RH temperature:-10℃-40℃,humidity:≤65%RH |

|

14.电源/ Power Supply | 380v |

|

15.外部单元External unit | 提供USB;232接口;Provide USB,232 interface. 选购:电脑,打印机或其他控制单元 Choose to buy: computer, printer or other control unit. |

|

16.阻抗测量(选购) Impedance measuring (choose to buy) | 1. 导体粉Conductor powder: 电阻范围resistance 10-7~2×107Ω 电阻率范围 resistivity 10-8~2×107Ω-cm 2. 绝缘粉Insulating powder: 电阻范围resistance 104Ω ~1×1016Ω |

|

金牌会员

金牌会员 已认证

已认证